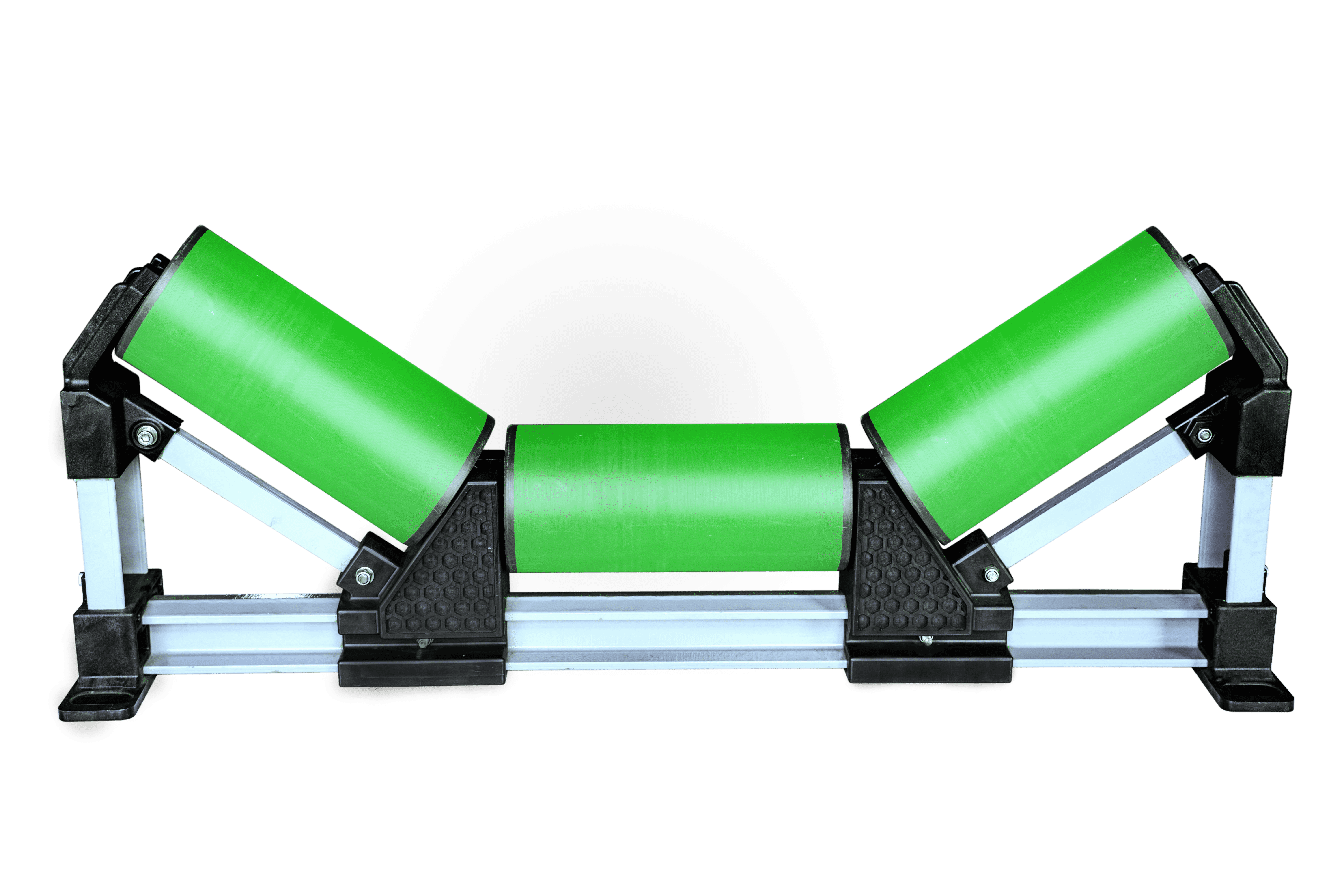

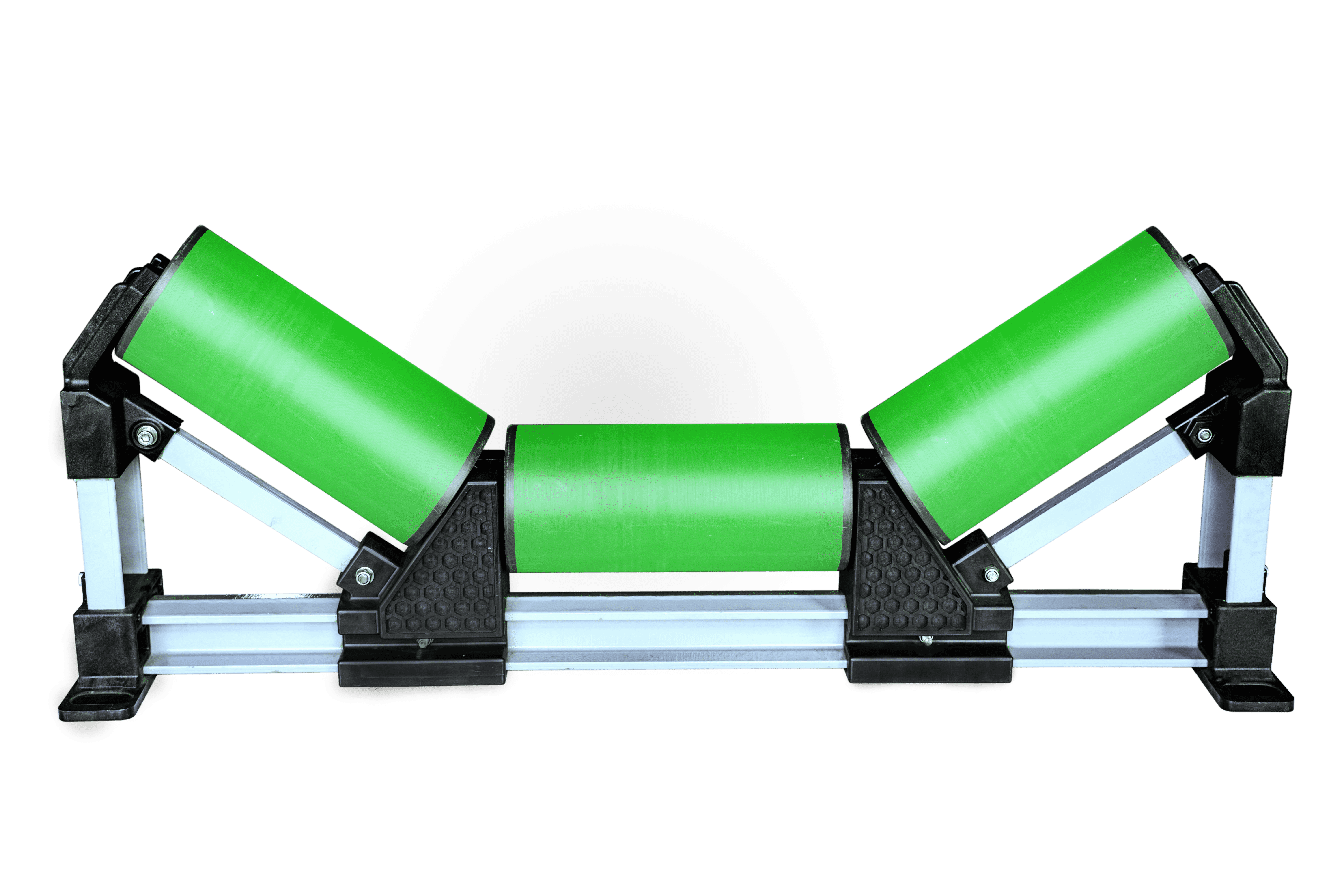

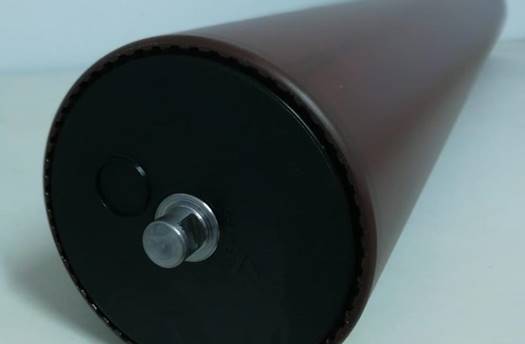

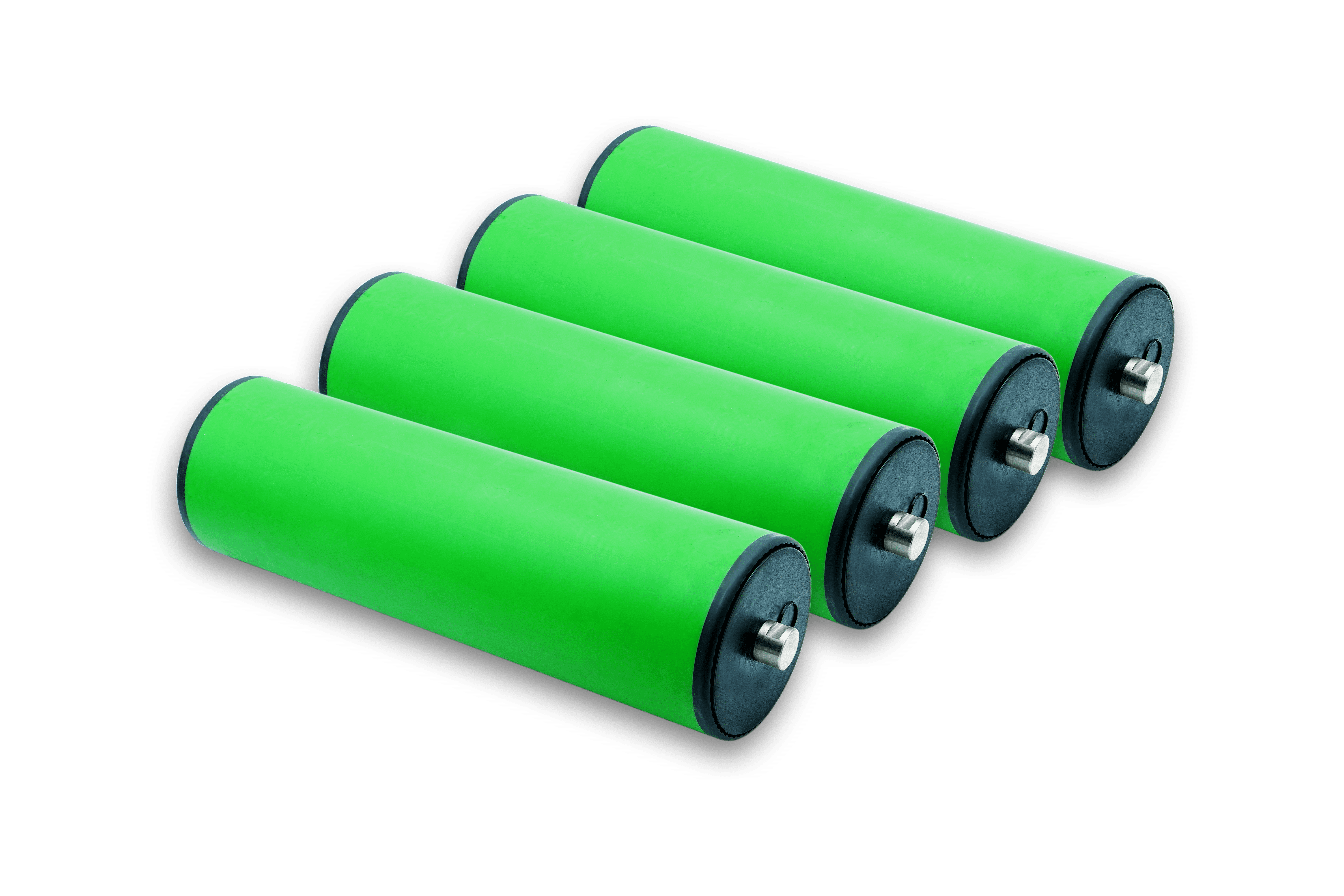

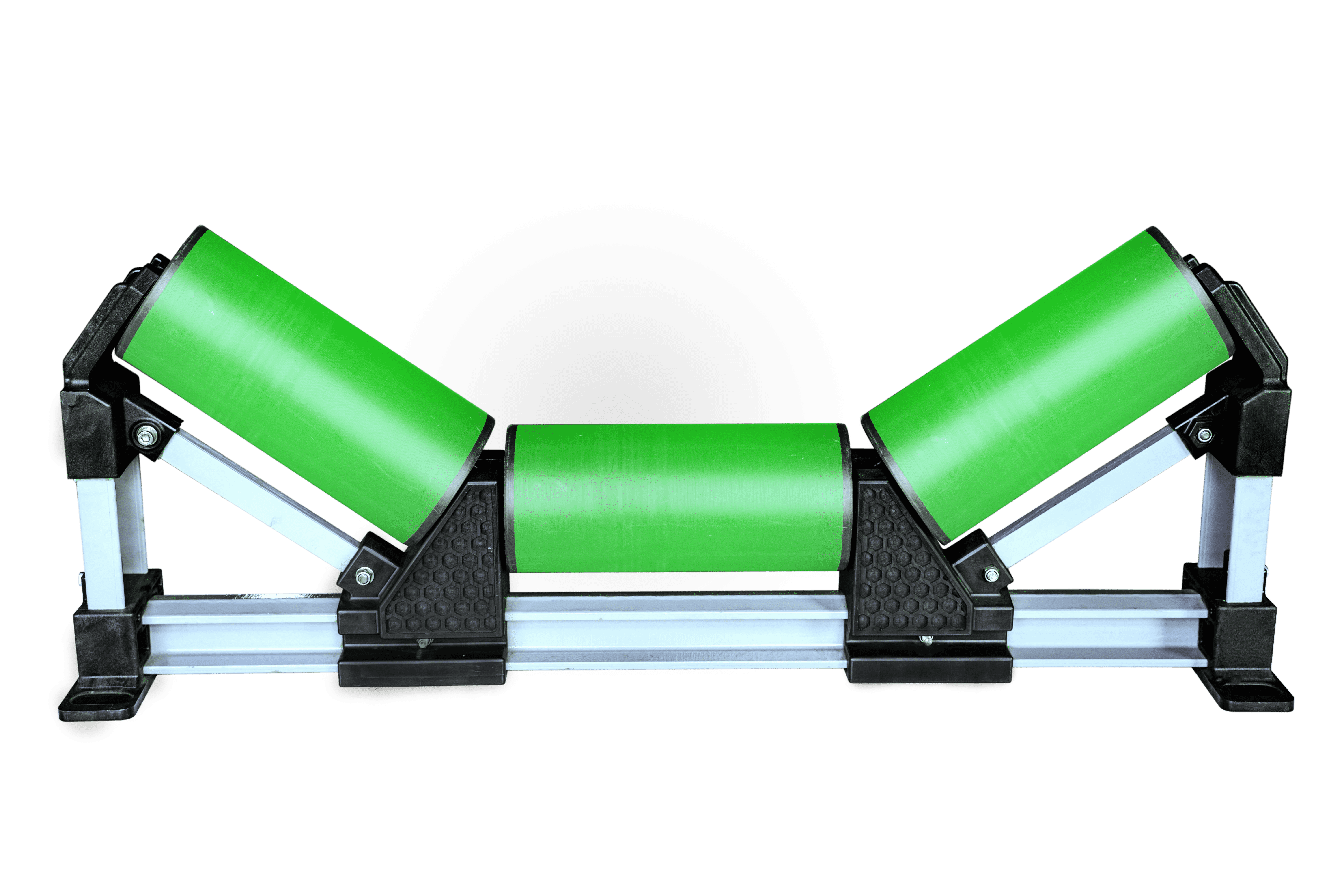

Composite Conveyor Roller

Light & Green Environment

| 1. | Standart Composite Glass Filled HDPE Roller |

| 2. | Standart Glass Filled Ultra-Hight Molecular Weight HDPE (UHM WPE) |

| 3. | Flame Retardant & Flame Retardant-Anti Static HDPE |

| 4. | Super High Rigidity Carbon Fibre Reinforced HDPE |

| 5. | Recycle BASE-Glass Filled HDPE |

| 6. | Impact Roller |

| 7. | Nylon Roller |

Nowadays forces us globally to find out both effective & efficient solution and forces us to do some recycle and reuse things The sophisticated of material handling is the present of composite material HDPE roller conveyor as an alternative solution now. Some of the benefits are as follow :

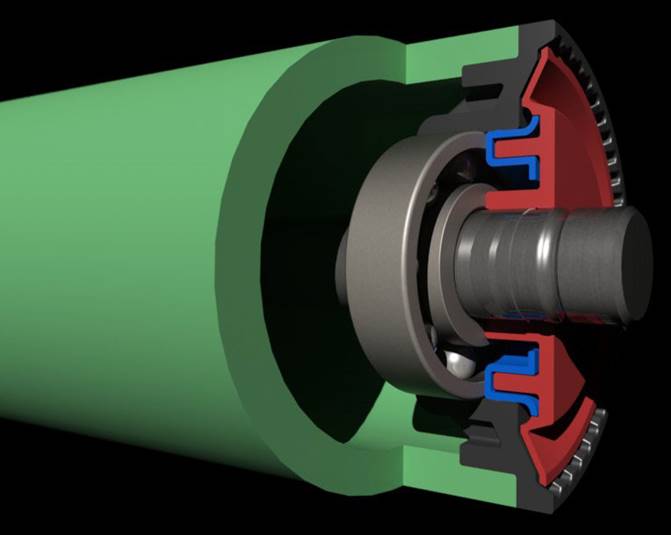

| Physical Properties | ||

| Density | 0.0338 - 0.0348 lb/in³ | 0.948 g/cc |

| Apparent Bulk Density | 0.021 - 0.022 lb/in³ | 0.59 g/cc |

| Water Absorption | 0.01 % | |

| Moisture Vapor Transmission | 0.965 cc-mil/100 in²-24hr-atm | |

| Environmental Stress Crack Resistance | 10 - 5000 hour | 1600 hr |

| Mechanical Properties | ||

| Hardness, Shore D | 58 - 65 | 62 |

| Tensile Strength, Ultimate | 3480 - 6530 psi | 30 MPa |

| Tensile Strength, Yield | 2180 - 4350 psi | 21.9 MPa |

| Elongation at Break | 500 - 1000 % | 840% |

| Tensile Modulus | 116 - 144 ksi | 0.86 GPa |

| Flexural Modulus | 72.5 - 220 ksi | 0.928 GPa |

| Izod Impact, Notched | 1.5 - 14.1 ft-lb/in | 3.7 J/cm |

| Izod Impact, Notched | 1.5 - 14.1 ft-lb/in | 3.7 J/cm |

| Tensile Impact Strength | 152 - 228 ft-lb/in² | 380 kJ/m² |

| Coefficient of Friction | 0.28 | |

| Thermal Properties Properties | ||

| CTE, linear 20°C | 77.8 µin/in-°F | |

| Melting Point | 255 - 268 °F | 130°C |

| Vicat Softening Point | 226 - 264 °F | 120°C |

| Brittleness Temperature | -148 - -94 °F | -86.2°C |

| No | Industries | Issue |

| 1. | Coal Fired Power Station (CFPP) | Corossion |

| 2. | Fertilizer | Corossion |

| 3. | Chemical or Petrochemicals | Corossion |

| 4. | Flourmills | Free of metal |

| 5. | Coal and mineral mining | Weight & Corossion |